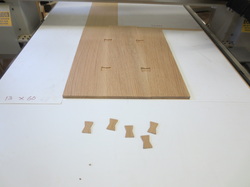

The video below shows how I can flatten a large surface using my CNC Router, Depending on the degree of variation in the surface this process may take a few passes to get it perfectly flat.

This particular piece was a older table top that the owner wanted to re-finish, so as well as flattening it I was able to remove the old finish.

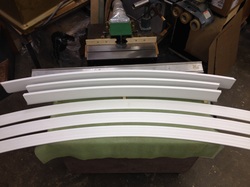

I stabilize the piece on the machine table so it cannot move , then I take a series of traverses using a large diameter flat bottom router bit ( called a " Table Mill ") once I have the first side flat I can then flip the piece over and to the same process on the opposite side.

Now this can be sanded and finished and you have a perfectly flat top. There may still be some deflection in the piece over time with changes in humidity and temperature.

Another very important item is that the top needs to be completely finished top, bottom, and all edges so that you can prevent moisture from penetrating into one surface more than another. This is referred to as a balanced finish.

RSS Feed

RSS Feed