I first apply a Lacquer based sealer that I have specially mixed to add a little bit of tint which gives the wood a little bit of a warm tone. (if I were doing a maple or something that required a "water clear" finish I would use a completely different product)

After the sealer is dry I hand sand with a 220 Grit sand paper, vacuum off the dust and spray with a Conversion Varnish. (a two part mix of varnish and catalyst as a hardener)

The finish I prefer is a "dull sheen" which gives a nice hand rubbed look but the protection of a sprayed top coat.

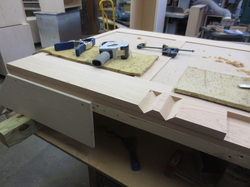

In this case The client wanted to hold off on the door and drawer fronts, and some of the trim details till a later date. (I'm glad that I was able to accomodate them with this, try to do that with another cabinet manufacturer)

"So we Loaded up the Truck and moved to Beverly" Jerico that is! And after a long day this was the result. Phase # 1 Complete.

RSS Feed

RSS Feed