By Taking the Time to do this answers alot of questions before you start to build. It also allows you to show the customer what the project will look like.

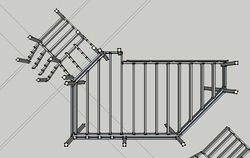

So after careful planning and precutting of various parts we spent the first day on site yesterday and after a long hot day we were able to get the main part of the deck frame erected, Take a look at the collection of photos below.

We'll be back a few nights this week, after the masons and Landscapers are out of the way and the sun starts to fade and continue with the process.

RSS Feed

RSS Feed